Plastic packaging, food and paper waste, and even tyre-wear particles could help power the net-zero transition by providing a sustainable source of materials for a new generation of battery technologies.

Techniques developed by researchers at Queen Mary University of London and Imperial College London could help provide raw materials needed for sustainable alternatives to conventional lithium-ion batteries.

A handful of critical chemical elements, including lithium, cobalt and graphite, power rechargeable batteries at the heart of everything from mobile phones to large-scale electricity grid storage.

Demand for these essential materials is set to grow as more countries move away from fossil fuels, and so will the environmental and geopolitical impacts of their mining and disposal.

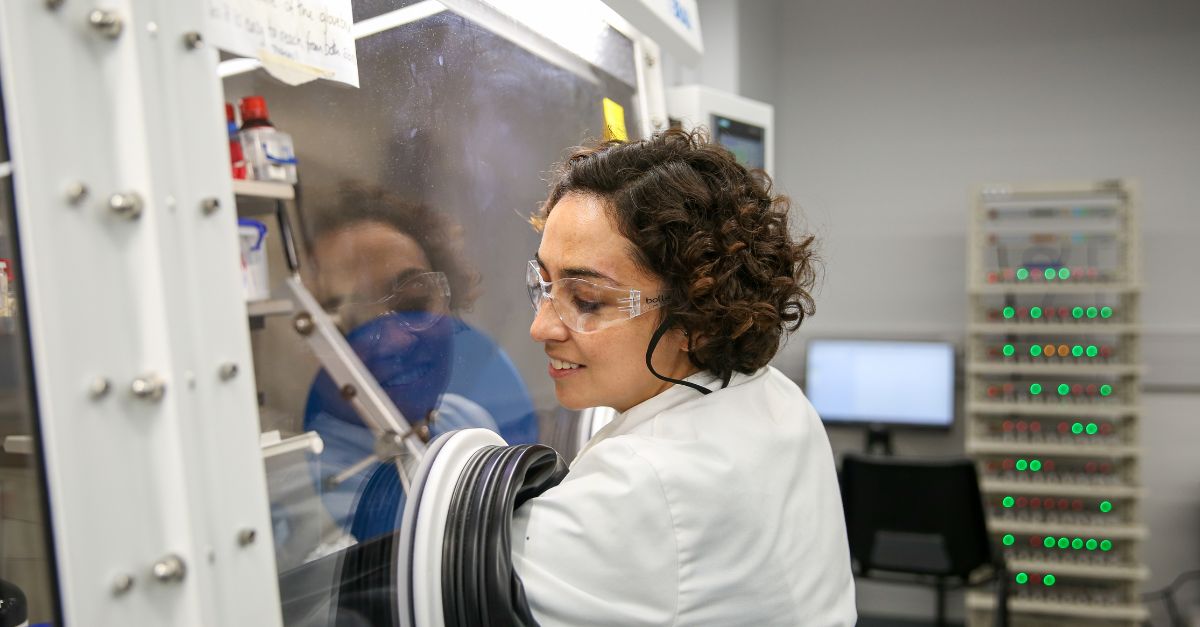

Dr Maria Crespo, lecturer in Green Energy at Queen Mary, will be exhibiting her team’s work on future batteries research at this year’s Royal Society Summer Science Exhibition, a free public festival of science held at the Society’s central London home from 2 – 7 July.

“Moving away from fossils fuels is an essential part of any plan to transition to net zero,” Dr Crespo said.

“However, if we continue to rely on lithium-ion batteries as the only option for fuelling our future, we are swapping one unsustainable, environmentally damaging resource for another.

“We need to diversify our batteries, so we are not relying on one group of scarce elements for every energy storage task, and we need to think much more carefully about how we reuse our materials when their lifespan is up.”

A 2023 review[1] forecast that, by 2040, demand for lithium, cobalt and nickel in electric vehicle batteries would outstrip production, but that improved recycling could meet up to half the raw material demands.

Dr Crespo estimates that for the UK to meet the 2050 energy storage requirements projected by the National Grid with lithium-ion batteries alone, would require lithium equivalent to 14 times the weight of The Shard, London[2].

But the critical elements used in lithium-ion batteries are relatively scarce. Lithium accounts for just 0.002% of the Earth’s crust and often elements like nickel and cobalt are found in geopolitically insecure regions or vulnerable ecosystems.

Last year, in collaboration with The Tyre Collective, Dr Crespo secured funds to transform particulates captured from vehicle tyres into components of sodium-ion batteries[3], an alternative to traditional lithium-ion batteries.

To be cost effective, alternative technologies like sodium-ion batteries, which have lower gram-for-gram energy storage potential, would have to be cheaper than lithium-ion to be cost effective.

Another recently patented technique[4] is looking at how rarely recycled nylon packaging, and other plastics, could be converted into hard carbon battery electrodes at relatively low temperatures, reducing the demand for virgin graphite.

Diversifying our battery chemistry, and the sources of raw materials, can also improve the sustainability and efficiency of lithium batteries, which will remain important for high-energy uses.

Dr Heather Au, Royal Society University Research Fellow at Imperial College London and a member of the exhibit team is researching lithium-sulfur batteries made with waste from the paper industry.

“When we need to use lithium for the large amount of energy it can store, we can replace the critical cathode materials, like cobalt and nickel, with sulfur, a cheap, abundant and non-toxic element,” Dr Au said.

“We can produce these electrodes using lignin, which is a waste product of paper manufacturing that is, currently, mostly burned for heating.

“The advantage of using our technology for lithium-sulfur systems is that they are much lighter than conventional electrodes, which could increase the gram-for-gram energy storage potential.”

Visitors to the Summer Science Exhibition will have a chance to talk to the researchers behind the work and try their hand at making batteries of their own.

- Maisel et al. 2023 A forecast on future raw material demand and recycling potential of lithium-ion batteries in electric vehicles. Resources, Conservation and Recycling –https://www.sciencedirect.com/science/article/pii/S0921344923000575#

- For reaching a target of 63 GWh of battery electrical storage in 2046. National Grid Electric System Operator, 2023, FES in Five, p. 10.

- Material Matters exhibition shows new batteries and pressure sensors developed from tyre wear particles – https://www.sems.qmul.ac.uk/news/6520/material-matters-exhibition-shows-new-batteries-and-pressure-sensors-developed-from-tyre-wear-particles/

- Upcycling plastic waste into high-capacity sodium-battery anodes – https://imperial.tech/wp-content/uploads/2024/05/11601_upcycling_plastic_waste_anodes_pub_MAY24.pdf