Switching Sheffield’s world-renowned steel forges from gas to locally produced green hydrogen could cut CO2 emissions by as much as 40%, a government-funded study supported by the city’s industry has found.

The city’s Blackburn Meadows renewable energy park is home to pioneering innovations headed by E.ON, assisted by Chesterfield Special Cylinders, the University of Sheffield’s Energy Institute and partners across the region.

The project explores ways to generate green hydrogen, for use by the city’s steelmakers and south Yorkshire’s energy-intensive industries.

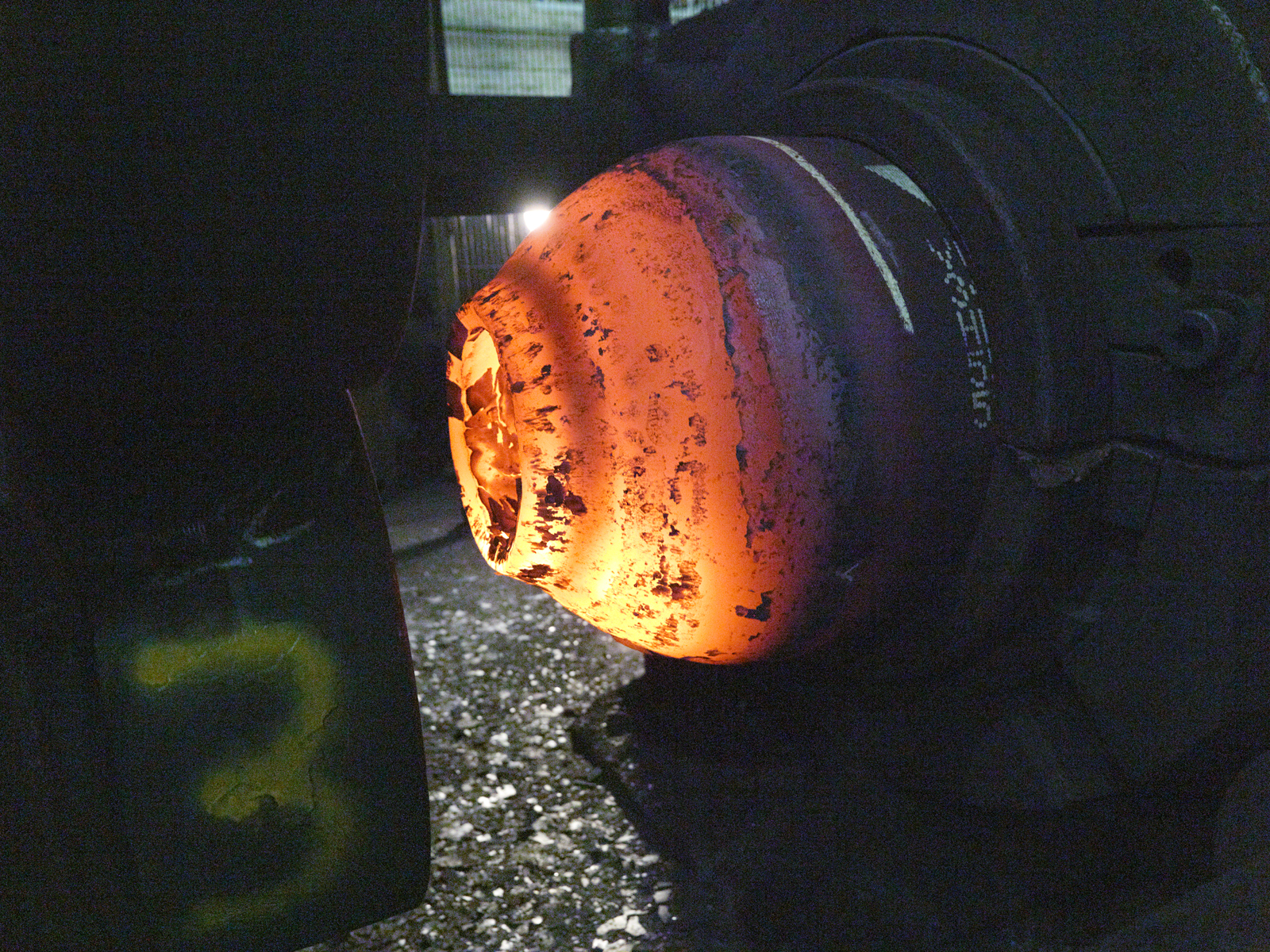

Strong desire from steelmakers has been unearthed in the project’s early stages to find a cleaner alternative to natural gas in firing forges and industrial processes. Operational findings from the trial’s three first manufacturers is that sustainable hydrogen maintains output quality, at the same time cutting emissions by 41.8% against natural gas. The three debutant manufacturers are on course to save 3,500 tonnes of CO2 per year.

£1 million of Government funding , from D-ESNZ’s £ 1 billion Net Zero Innovation Portfolio (NZIP) backs the Yorkshire partners’ desk assessment of commercial and engineering needs in generating, transporting and using hydrogen, as well as developing its commercial offer to industrial customers. If that is successful, the next stage will be a technical pilot project at the Blackburn Meadows sewage processor site, on the city’s fringes at Tinsley. Expansion could follow, if the project is taken forward to a full commercial demonstration.

E.ON leads the initiative alongside Chesterfield Special Cylinders, Glass Futures, University of Sheffield Energy Institute and Sheffield Forgemasters.

Chris Lovatt, E.ON’s UK Solutions’ chief operating officer, said: “Hydrogen will play a significant role in our energy future, mainly powering energy-intensive industries and long-distance transport. It sits alongside the drive for heat pumps meeting domestic heating needs and a greater role for district energy schemes in urban areas.

“The first stages of our trial show the technology works and can support the industry’s needs for alternative fuels as well as Sheffield’s wider sustainability ambitions. We know there are challenges to overcome before this becomes a viable solution for industry but the success so far has been rewarded by further funding from Government to explore the potential of green hydrogen as a solution for Sheffield’s world-renowned steelmakers.”

From Sheffield Uni’s Energy Institute, Professor Mohamed Pourkashanian responded: “We are thrilled that this project has received funding from the UK Government to progress to a second stage.

The work we’re doing for this project at our Energy Institute, including computational Fluid Dynamic (CFD) modelling and in-depth hydrogen research, will help bring us a step closer to vital industrial decarbonisation and beyond.

“It is increasingly important to get the technological solutions we need to reduce emissions right first time, so carrying out these detailed and industry-supported projects at the University of Sheffield Energy Institute means we can test, scale and ultimately implement these alternative solutions as efficiently as possible.”

Hydrogen can be used for reducing iron ore to pig iron as well as providing the heat energy for reheating steel prior to forging, so it is not clear from the aricle if it is just for reheating or als for reducing the iron ore or both. If it is just for reheating then another fossil free energy source could be biomethane produced from organic waste, in particular food waste and sewage. Since local councils are now required to collect food waste separately (since 01/04/23) there should be plenty available for making fossil free methane which is easier to use in existing heating equipment at Sheffield Forge Masters.